The Beechcraft Starship is a

futuristic-looking aircraft designed by Burt Rutan's

Scaled Composites, and produced by the Beech

Aircraft Corporation. It is a six- to eight-seat

business transport.

Development cost $300 million, and began in 1979

when Beechcraft identified a need to replace the

King Air model. After a brief hiatus while the

company was bought by Raytheon, full development

began in 1982 when Beechcraft approached Burt Rutan

of Scaled Composites, a leader in the field of novel

composite aircraft design. Much of the design work

utilised computer-aided design, using the CATIA

system.

While in development at Scaled, the 85%-scale

prototype was the Model 115, and Beechcraft referred

to the production version as the Model 2000. The

Model 115 first flew in late August 1983. However,

this aircraft had no pressurization system, no

certified avionics, and had a different airframe

design and material specifications than the planned

production Model 2000. This aircraft has since been

scrapped.

The first full-size Starship flew on February 15,

1986. Prototypes were produced even as development

work was continuing -- a system demanded by the use

of composite materials, as the tooling required is

very expensive and has to be built for production

use from the outset. The program was delayed several

times, at first due to underestimating the

development complexity involved and later to

overcome technical difficulties concerning the

stall-warning system.

The first production Starship flew in late 1988.

The Starship was notable for several reasons. First

was its all-graphite composite airframe, using

high-tech materials instead of aluminium. These

materials were in frequent use to varying degrees on

military aircraft, but no civilian aircraft

certified by the FAA had ever used them so

extensively. Composites were chosen in order to

reduce the weight of the airplane which,

unfortunately, still came in over its target weight.

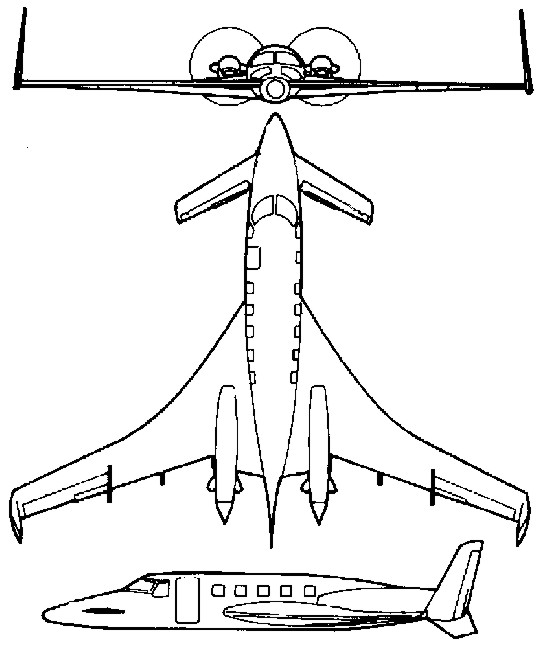

Second was its canard design, with the lifting

surface aft of the horizontal stabilizer. The

aircraft lacks a rudder, with yaw control instead

provided by small fins on the wingtips.

Third was its use of a pusher design, in which the

turboprop engines were mounted facing the rear and

pushed, rather than pulled, the aircraft forward.

The pusher design offers a quieter ride, since the

gusts of wind and air off the tips of the propellers

no longer strike the side of the aircraft, as they

do on conventionally configured turboprops.

The aircraft also features a 16-tube "glass cockpit"

supplied by Rockwell Collins Avionics.

Commercially the aeroplane was a failure, with

little demand. Only 53 Starships were ever built,

and of those only a handful were sold. Many of the

remainder were eventually leased.

Reasons for the lack of demand probably included

price, performance, and economic conditions. The

list price in 1989 was $3.9 million, similar to the

Cessna Citation V and Lear 31 jets, which were 89

and 124 knots faster than the Starship at maximum

cruise, respectively. The Piper Cheyenne turboprop

was faster and sold for $1 million less. (Aviation

Week, Oct. 2, 1989).

In 2003, Beechcraft deemed that the aircraft was no

longer popular enough to justify its support costs,

and has recalled all leased aircraft for scrapping.

The company is also said to be aggressively trying

to buy back privately-owned Starships, though some

Starship owners say they have never been contacted

by Raytheon about this.

Most of the Starships are being ground up and burned

at the "boneyard" at the Evergreen Air Centre. The

planes have little aluminium for recycling. A few

have been bought up by private owners who regard

them as lovable failures, much like the infamous

Ford Edsel.

Recently, Starship Model 2000A NC-51 was used as a

chase plane during the re-entry phase of Burt

Rutan's SpaceShipOne. Several Starships have been

donated to museums since the official

decommissioning program began, with the Kansas

Aviation Museum receiving the first aircraft in

August of 2003.

Why the Starship sell well

1) Revolutionary design.

The aviation community accepts new concepts slowly and evolution is

generally preferred over revolution. While many potential buyers were

awestruck by the Starship's beauty, most chose to sit on the fence for a

few years to see if the Starship proved to be a viable design. The

Starship was radically different from conventional aircraft when

introduced in the mid 1980's and heralded four revolutionary technologies:

a) First certificated all glass cockpit and FMS

b) First certificated all composite business class aircraft (still

the only certificated composite wing)

c) First certificated tandem wing (canard) aircraft.

d) First certificated pusher

We all now know that the glass cockpit is superior to steam gauges and

that composites are superior to metal for airframe construction. The

canard vs. conventional configuration is still a topic of heated debate,

however. All I can say is, why in the world would you want to have a

stabilizer that pushes DOWN when the basic purpose of an aircraft is to

lift you into the air? I know, it's stability, stupid. But you get the

same stability with a canard design while gaining about 5% in efficiency.

It's also debatable that the pusher configuration is any better than a

tractor design and it's generally accepted that a pusher is no more

efficient than a tractor. That's because the airflow to the props is

disturbed by the fuselage and wing ahead of them. But a pusher definitely

creates a much quieter cabin than a tractor. The Starship is extremely

quiet inside and the cabin noise levels seem more like a jet than a

turboprop. Normal conversations can be had without raising your voice. A

pusher design also allows the propellers to be mounted very close together

because they don't have a fuselage between them. The Starships props are

only inches apart, yielding nearly centreline thrust from each engine.

During an engine out situation in the Starship, yaw is virtually

unnoticeable and is completely countered by the yaw damper, if engaged; No

need to step on the dead engine.

2) Raytheon

This section is based on my experience as the owner / pilot of Starship

NC-51 and with conversations I have had with other Starship owners,

Raytheon employees, RAS employees and other aviation professionals who

know the Starship program intimately. I am interested in sharing what I

have experienced and heard. It is not my intention to criticize Raytheon,

RAS or their management.

a) Timing

Raytheon had lousy timing when it came to the Starship. The aircraft was

introduced to an anaemic market in 1989 during the height of an economic

recession. You couldn't give away an executive aircraft during this

period, let alone successfully promote an all new design. So Starship

sales got off to a very disappointing start.

But by 1995 the economy had become robust and corporate expenditures for

new aircraft were in a cyclical upturn. Just as important, the Starship's

all glass cockpit and composite structure had become accepted as superior

art by the aviation community. This is precisely the period when Raytheon

could have made a success of the Starship. In 1995 Raytheon should have

"put the pedal to the metal" to promote the Starship's superb safety

record and exceptional ride. But instead, Raytheon opted to pull the plug

on Starship production. Bad timing, again.

b) Price

Unfortunately, Raytheon priced the Starship at almost $5,000,000. This was

way more expensive than the King Air that the Starship was intended to

replace and was virtually the same price as an introductory jet at that

time. 3.5 to 4 million dollars would have been a more realistic price

point for the Starship.

c) Free Maintenance

To help boost Starship sales, Raytheon management had the brilliant idea

of offering free maintenance to buyers. In the end, this program probably

had more to do with Raytheon's decision to discontinue the Starship than

anything else and helped falsely earn the Starship a reputation of being a

maintenance hog.

Raytheon Aircraft Services (RAS) was responsible for doing the "free"

maintenance for Starship owners. To understand what happened, it's

important to point out that RAS is a separate company from Raytheon.

As with any service business, aircraft maintenance has its slack periods.

But when RAS facilities had slack periods in the early 90's, many of them

found Starships on the ramp to work on. They would work on the Starships

whether they needed it or not and many of these airplanes were still owned

and operated by Raytheon.

Even if the Starship was owned by a private party, owners didn't care how

big the invoice was because Raytheon was paying the tab. With nobody

questioning the invoices, one can imagine the scale of the billings that

took place.

Periodically, Raytheon would ask RAS to explain why the Starship fleet was

so expensive to maintain. And naturally, RAS would respond that the

Starship was a very complex airplane that was difficult to work on.

Raytheon accepted these claims and continued paying the maintenance bills.

But in reality, the free maintenance program was a billing machine for RAS

and nobody at Raytheon had the incentive to figure it out and end it..

So free maintenance resulted in record billings to Raytheon, souring

management's view of the Starship and frightening prospective customers.

Raytheon management bought the RAS line that the Starship was complex and

difficult to work on, eventually putting the red ink to bed by killing

Starship production.

As an aside, my Starship is not maintained by RAS. NC-51's maintenance

costs have been lower than I originally budgeted for a King Air B-200. In

the 7+ years I have owned NC-51, I have been able to depart on 698 out of

over 700 flights (a 99.7% dispatch rate). I'll put that record against any

airplane in existence.

3) The FAA

Before the Starship came along, the FAA had never certificated a composite

airframe, so they were naturally very cautious when approached with the

Starship design. In an effort to err on the safe side, the FAA essentially

told Beech that although their design looked good on paper, the design

would have to be significantly strengthened to receive certification.

Beechcraft did so, adding significant additional structure to both the

fuselage and wing. Of course, this added quite a bit of weight to the

aircraft, so other components had to be beefed up as well, adding yet more

weight.

In the end, the Starship's max ramp weight rose by over 2,500 lbs to

15,010 lbs. All of these trips back to the drawing board had another

detrimental effect; Certification, production and customer delivery of the

first airframes kept slipping, slipping, slipping, into the future.

The original design was to be less than the FAA's 12,500 lb. limit for non

type rated operation. But the redesigned Starship ended up requiring a

type rating to fly, and many owner operators were intimidated by the

prospect of going through the type rating process. Those pilots chose

other aircraft such as Beech's venerable King Air instead, which could be

flown with a simple twin engine rating.

The higher weight of the Starship also reduced Beech's projected

performance claims for the Starship. The Starship was supposed to have a

max cruise speed of 352 knots, a useful load of 4,599 lbs, stall at 79

knots and fly for over 2,500 nm at max range power. But after the FAA was

done beefing up the airframe, those numbers became 338 knots, 4,710 lbs,

89 knots and 1,575 nm respectively. But even with the extra weight and

reduced performance, the Starship still outperformed the King Air B-200.

This is an amazing thing, and speaks volumes for the strength of the

Starship's original design.

How many other aircraft designs could even fly after such a weight gain,

let alone climb to 41,000 feet? All this while actually increasing the

useful load by 111 lbs. The Starship is a truly great aircraft, even with

her extra heft. Imagine how fabulous the Starship would have been if the

FAA had certificated her original design.

Powerplants

Two 895kW (1200shp) Pratt & Whitney Canada PT6A67As, driving five blade

constant speed McCauley propellers.

Performance

2000 - Max cruising speed 622km/h (335kt), economical cruising speed

546km/h (295kt). Initial rate of climb 3225ft/min. Max range 2630km

(1634nm). 2000A - Max cruising speed 621km/h (335kt), economical cruising

speed 570kt (307kt). Initial rate of climb 2748ft/min. Range with reserves

2920km (1576nm).

Weights

2000 - Empty equipped 4484kg (9887lb), max takeoff 6531kg (14,400lb).

2000A - Empty equipped 4574kg (10,085lb), max takeoff 6758kg (14,900lb).

Dimensions

Wing span 16.60m (54ft 5in), length 14.05m (46ft 1in), height 3.94m (12ft

11in). Wing area 26.1m2 (280.9sq ft).

Capacity

Flightcrew of one or two pilots. Standard passenger layout for eight in

2000 or six in 2000A.