The Bede BD5 was the kit aircraft that firmly established Bede's

reputation as the 'bad boy of the kit building industry'.

Few airplanes in the history of

aviation have fired public imagination like the

build-it-at-home-from-a-kit BD-5. It promised tremendous performance

at a minimal cost in money to purchase and operate, and time and

space to build. James R. Bede had ambitious plans for this aircraft.

His poor execution of those plans, and the ultimate failure of the

original BD-5 concept, should not obscure the many original and

innovative aspects of this design.

By 1970, Bede (pronounced 'beedee')

had earned a reputation for designing and flying innovative,

high-performance aircraft. Factories produced more than 1,700

examples of his BD-1 (production designation AA-1). This was the

first light aircraft mass-produced using bonded (glued) metal

construction. A BD-2 soon followed. Bede designed this airplane to

fly non-stop around the world without refuelling. He did not make

the flight but the project stirred considerable interest among

designers and pilots. Bede pushed the kitplane design envelope again

with the BD-4 by building the wing using his patented "panel-rib"

process. The four-seat BD-4 was moderately successful and Bede sold

about 600 kits. This encouraged him to push the design and

performance envelope further on his next project.

Bede began to refine the concept

of the BD-5 as early as 1967 but the demands of other projects

slowed the work. By 1970, he had progressed far enough to begin

selling information packets and on February 24, 1971, he accepted

the first deposit from a prospective builder to reserve a BD-5 kit.

The airplane had yet to fly, but marketing hype had already

displaced common sense in the minds of many homebuilt enthusiasts.

Jim Bede first flew the BD-5

prototype on September 12, 1971. Public interest in the tiny

speedster soared and by December, the company had received 4,000 kit

orders. A kit consisted of different materials that the builder

formed, cut, drilled, bonded, or riveted into a finished BD-5. The

first kits cost $2,100. For toiling about 300-400 hours (assembly

time claimed in the advertisements as a rough average, but one owner

spent 7 years and $20,000), a builder could expect to finish an

airplane that looked and flew like no other.

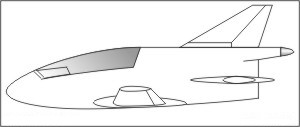

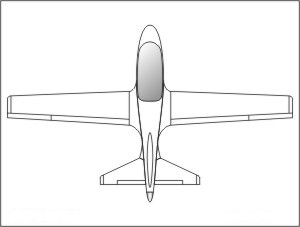

Pictures of the prototype showed a

sharp, smooth nose that flowed back to an exotic, vee-tail. The

single-seat fuselage was miniscule, barely 4 m (13 ft) long, but

this appealed to homebuilders who were loath to take on projects

that required more space than a garage or apartment. The wing was

mounted low and spanned just over 6.4 m (21 ft) and the airplane

took-off and landed on tiny, retractable, tricycle landing gear. The

factory offered a set of shorter wings (4.3 m/14 ft 4 in span) but

almost no one flew with them. With the long wings attached, the

airplane officially became the BD-5B.

In the hands of a qualified pilot,

the BD-5 could perform a full range of aerobatic manoeuvres.

Virtually everyone who flew the '5 called the handling qualities at

speed and altitude delightful. Control pressures were very light

because Bede plumbed the control circuits with push-rods supported

on ball bearings. One pilot described how he simply 'thought'

himself into a turn, without consciously moving the stick or rudder

pedals. On takeoff, these same characteristics could cause

inexperienced pilots to over-rotate the nose on takeoff to

dangerously high angles. There was no fix for this characteristic

and pilots new to flying the BD-5 receive stern warnings to use tiny

movements on the control stick. Bede fixed the lack of directional

stability as soon as flight-testing began late in September 1971. A

conventional horizontal stabilizer, elevator, vertical fin and

rudder replaced the vee-tail.

Maximum cruise speed was

impressive at 322 kph (200 mph). The BD-5 weighed about 270 kg (600

lb), and it could fly slowly, and even soar like a motorglider,

according to the slick brochures. Bede claimed that the powerplant

sipped just 4 gallons per hour of fuel to give the BD-5 the range to

fly about 1,610 km (1,000 miles) at a ceiling of 4,256 m (14,000

ft). After some practice, a competent pilot could land or take off

in 152-182 m (500-600 ft).

To enable a BD-5 to achieve this

performance level, a very special engine had to propel the kitplane.

Such an engine did not exist. Initially, the BD-5 came with a

two-cylinder, two-cycle, in-line and air-cooled Keikaefer power

plant that made 40 horsepower. This engine proved unreliable so Bede

began a frantic hunt for a substitute. He tried the Hirth two-cycle

engine and announced that a builder could order one of three models

for the BD-5: a 40, 55, or 70 horsepower version. In addition to the

kit, Bede announced a full production version designated the BD-5D,

and promised to certify this model and sell it for $4,400, but the

factory never built this model. The factory did complete about 3,000

kits.

Most builders found the kits

extremely difficult to work on. They had to fabricate many complex

parts including the drive system required to transmit power from the

engine to the propeller. After Hirth announced that the firm could

not supply enough power plants to meet projected kit sales, the most

difficult problem for BD-5 kit owners remained the engine and Bede

never found a suitable alternative. He tried motors from Polaris,

Zenoah, Kawasaki, and others without success.

By the late 1970s, Bede had run

out of time to save the BD-5. Many of the people who bought kits

began to sell them at a fraction of initial cost. Hoping to generate

cash, Bede dabbled briefly with a sailplane version, and his

jet-powered BD-5 became popular at airshows. By 1979, Bede was

bankrupt and the BD-5 kitplane saga ended. Budd Davisson summed it

up well when he said: "Too much was said early in the game, promises

were made, performance figures quoted and money taken. So, when

things didn't go like clockwork, the BD buying public got a little

bit ticked off."

To this day, the BD-5 remains a

compelling airplane. About 150 were flying in 2002, primarily

because entrepreneurs formed several companies to supply knowledge,

experience, and hardware to BD-5 builders. The Bede factory shipped

kits that consisted of little more than raw materials but no engines

and drive trains. During the mid-1970s, Keith Hinshaw organized Bede-Micro

Aviation in San Jose, California, and focused the business on

supplying a solution to the engine problem, and supplying parts and

assistance to builders. Keith was a former BD-5 owner and dealer. He

and his staff had one workable solution to the engine problem, a

turbo-charged Honda automobile engine. This engine is installed in

the NASM BD-5. Bede-Micro improved other aspects of the BD-5. They

designed and sold parts and plans to strengthen the wings and the

top of the rudder, improved the landing gear and flaps, and stretch

the fuselage 5 inches to accommodate different engines. Bede-Micro

was still providing support, parts, and upgraded kits for the BD-5

in 2002.

A jet version was developed and

became famous for flying through a hanger in a James Bond movie

It is not permitted to fly this aircraft in the UK