Most aircraft have several instruments that are traditionally

driven by mechanical Gyros. These instruments assist in flying and navigation of

an aircraft. These instruments are the Attitude Indicator (also known as the

Vertical Gyro), the Directional Gyro, and the Turn and Bank Indicator. Aircraft

also typically have a compass, and in some cases a Flux Valve (also known as a

Magnetometer) to which the Directional Gyro is connected or slaved to cancel

long term drift. If the aircraft does not have an electronic Flux Valve, then

the Directional Gyro or DG has to be manually reset to the compass reading

during straight and level flight (when the compass is accurate) on a periodic

basis. In most light aircraft the Turn Coordinator (TC) is electrically

driven. Usually the Heading Indicator (HI) and Attitude Indicator (AI) are

vacuum driven.

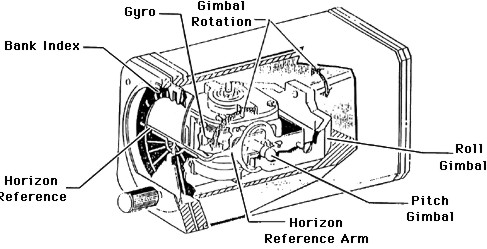

The three Gyro instruments, Attitude Indicator, Directional

Gyro and Turn and Bank Indicator are ‘gyro’ driven. What does gyro-driven mean?

A gyro is a spinning wheel (mass) that obeys the Laws of Physics. The spinning

wheel is spun up either electrically (electric gyros) or via air flow (vacuum

gyros) to high rotational speeds and a high angular momentum. The spinning wheel

is mechanically isolated from the casing of the instrument thru a series of

gimbals. Due to the conservation of angular momentum, the spinning wheel will

try to maintain its orientation, via the gimbals, as the outer casing moves. The

outer casing is of course connected to the airframe. The gimbals, move by the

amount the aircraft has rolled, pitched, or changed heading, and in some cases

directly connect to the display. The display provides an indication of the

aircraft attitude. In the case of a remote gyro and also with many electric

gyros, the gimbals provide an analogue electrical output proportional to

aircraft orientation change.

gyroscopic

principles

Any spinning object possesses gyroscopic characteristics. The

central mechanism of the gyroscope is a wheel similar to a bicycle wheel. It's

outer rim has a heavy mass. It rotates at high speed on very low friction

bearings. When it is rotating normally, it resists changes in direction.

The gyroscope exhibits two predominant characteristics:

-

Rigidity in Space

-

Precession

rigidity in

space

The gyroscope resists turning. When it is "gimballed" ( free

to move in a given direction) such that it is free to move either in 1, 2 or 3

dimensions, any surface such as an instrument dial attached to the gyro assembly

will remain rigid in space even though the case of the gyro

turns. The Attitude Indicator (AI) and the Heading

Indicator (HI ) use this property of rigidity in space for

their operation. The HI responds only to change of heading.

The AI responds to both changes in Pitch and in Roll.

precession

Precession is the deflection of a spinning wheel 90 ° to the

plane of rotation when a deflective force is applied at the rim. If a force is

applied the top of the rim (the plane of rotation), the precession (turn) will

be 90° in the horizontal plane to the left. The Turn Coordinator (TC)

uses this precession property. For example, then taxiing on the ground, the Turn

Coordinator will move, with the small airplane in the instrument showing a bank,

even though the aircraft is level. The banking of the small aircraft

presentation indicates only that the aircraft is turning.

the vacuum

system

The Attitude Indicator (AI) and the

Heading Indicator (HI) in light aircraft are usually driven by a vacuum

system. The principal components are shown below. Not shown are auxiliary

devices such as valves, filters etc. A pump provides the vacuum to the AI and HI

through a system of vacuum lines. A Vacuum Gauge is attached to the lines which

gives the pilot an indication that adequate vacuum is being generated.

gyro power sources

Air or electricity supply the power to operate gyro instruments in light

aircraft. If the directional indicator and attitude indicator are air-driven (as

they generally are), the turn-and-slip indicator is electrically powered. The

advantage of this arrangement is that if the vacuum system (which supplies air)

fails, the instrument pilot still has the compass and the turn indicator for

attitude and direction reference, in addition to the pitot-static

instruments.

1. vacuum power system: Air-driven gyros normally are powered by a vacuum

pump attached to and driven by the engine. Suction lines connect the pump to the

instruments, drawing cabin air through the filtered openings in the instrument

case. As the air enters the case, it is accelerated and directed against small

"buckets" cast into the gyro wheel. A regulator is attached between the pump and

the gyro instrument case to control suction pressure. There is normally a vacuum

gauge, suction gauge (See the Typical Suction Gauge figure,

below) or warning light. Because a constant gyro speed is essential for

reliable instrument readings, the correct suction pressure is maintained with a

vacuum pressure regulator.

The air is drawn through a filter, to the instruments and then to the pump

where it is vented to atmosphere. The pilot should consult the aircraft

operating manual for specific information with regard to vacuum system normal

operating values. Low gyro rotation speeds cause slow instrument response or

lagging indications, while fast gyro speeds cause the instruments to overreact

in addition to wearing the gyro bearings faster and decreasing gyro life.

2. electrical power system: An electric gyro, normally used to drive the turn

coordinator or turn-and-slip indicator, operates like a small electric motor

with the spinning gyro acting as the motor armature. Gyro speed in these

instruments is approximately 8,000 rpm.

Aircraft that normally operate at high altitudes do not use a vacuum system

to power flight instruments because pump efficiency is limited in the thin, cold

air. Instead, alternating current (a.c.) drives the gyros in the heading and

attitude indicators. The a.c. power is provided by inverters that convert direct

current to alternating current. In some cases, the a.c. power is supplied

directly from the engine-driven alternator or generator.