the jet engine components

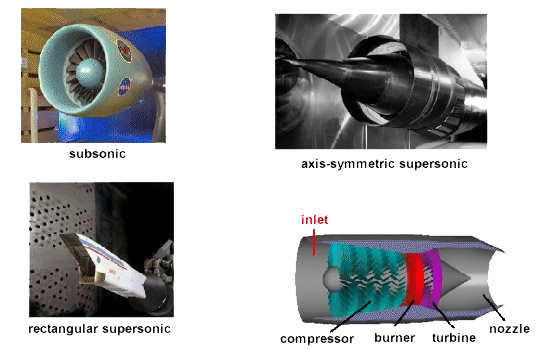

inlets

All turbine

engines have an inlet to bring free stream air into the

engine. The inlet sits upstream of the compressor and, while

the inlet does no work on the flow, there are some important

design features of the inlet. As shown in the figures

above, inlets come in a variety of shapes and sizes with the

specifics usually dictated by the speed of the aircraft.

subsonic

inlets

For aircraft

that cannot go faster than the speed of sound (like large

airliners), a simple, straight, short inlet works quite well.

On a typical subsonic inlet, the surface of the inlet, from

outside to inside, is a continuous smooth curve with some

thickness from inside to outside. The very front (most

upstream portion) of the inlet is called the highlight,

or the inlet lip. A subsonic aircraft has an inlet with

a relatively thick lip.

supersonic

inlets

An inlet for a

supersonic aircraft, on the other hand, has a relatively sharp

lip. The inlet lip is sharpened to minimize the performance

losses from shock waves that occur during supersonic flight.

For a supersonic aircraft, the inlet must slow the flow down

to subsonic speeds before the air reaches the compressor. Some

supersonic inlets, like the one at the upper right, use a

central cone to shock the flow down to subsonic speeds. Other

inlets, like the one shown at the lower left, use flat hinged

plates to generate the compression shocks, with the resulting

inlet geometry having a rectangular cross section. This kind

of inlet is seen on the F-14 and F-15 fighter aircraft. There

are other, more exotic inlet shapes used on some aircraft for

a variety of reasons.

inlets

efficiency

An inlet must

operate efficiently over the entire flight envelope of the

aircraft. At very low aircraft speeds, or when just sitting on

the runway, free stream air is pulled into the engine by the

compressor. In England, inlets are called intakes,

which is a more accurate description of their function at low

aircraft speeds. At high speeds, a good inlet will allow the

aircraft to manoeuvre to high angles of attack and sideslip

without disrupting flow to the compressor. Because the inlet

is so important to overall aircraft operation, it is usually

designed and tested by the airframe company, not the engine

manufacturer. But because inlet operation is so important to

engine performance, all engine manufacturers also employ inlet

aerodynamicists.

compressors

All turbine engines have a

compressor to increase the pressure of the incoming air

before it enters the combustor.

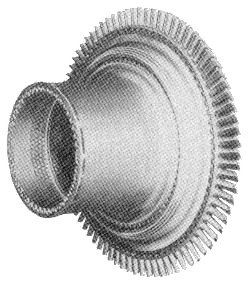

As shown in

the above figure, there are two main types of compressors:

axial and centrifugal. The compressor on the left is called an

axial compressor because the flow through the compressor

travels parallel to the axis of rotation. The compressor on

the right is called a centrifugal compressor because the flow

through this compressor is turned perpendicular to the axis of

rotation. Centrifugal compressors, which were used in the

first jet engines, are still used on small turbojets and

turboshaft engines and as pumps on rocket engines. Modern

large turbojet and turbofan engines usually use axial

compressors.

An axial flow compressor

(stators omitted for clarity). This is the high pressure

compressor from a General Electric F404 engine

Why the change

to axial compressors? An average, single-stage, centrifugal

compressor can increase the pressure by a factor of 4. A

similar single-stage axial compressor increases the pressure

by only a factor of 1.2. But it is relatively easy to link

together several stages and produce a multistage axial

compressor. In the multistage compressor, the pressure is

multiplied from row to row (8 stages at 1.2 per stage gives a

factor of 4.3). It is much more difficult to produce an

efficient multistage centrifugal compressor because the flow

has to be ducted back to the axis at each stage. Because the

flow is turned perpendicular to the axis, an engine with a

centrifugal compressor tends to be wider (greater

cross-sectional area) than a corresponding axial. This creates

additional undesirable aircraft drag. Centrifugal compressors

are also less efficient than axial compressors. For all of

these reasons, most high compression jet engines use multi

staged axial compressors. But, if only a moderate amount of

compression is required, a centrifugal compressor is much

simpler to use.

The combustion chamber has the difficult task of burning large

quantities of fuel, supplied through fuel spray nozzles, with

extensive volumes of air, supplied by the compressor, and

releasing the resulting heat in such a manner that the air is

expanded and accelerated to give a smooth stream of uniformly

heated gas. This task must be accomplished with the minimum

loss in pressure and with the maximum heat release within the

limited space available.

The amount of fuel added to the

air will depend upon the temperature rise required. However,

the maximum temperature is limited to within the range of 850

to 1700 °C by the materials from which the turbine blades and

nozzles are made. The air has already been heated to between

200 and 550 °C by the work done in the compressor, giving a

temperature rise requirement of 650 to 1150 °C from the

combustion process. Since the gas temperature determines the

engine thrust, the combustion chamber must be capable of

maintaining stable and efficient combustion over a wide range

of engine operating conditions.

The temperature of the gas after

combustion is about 1800 to 2000 °C, which is far too hot for

entry to the nozzle guide vanes of the turbine. The air not

used for combustion, which amounts to about 60 percent of the

total airflow, is therefore introduced progressively into the

flame tube. Approximately one third of this gas is used to

lower the temperature inside the combustor; the remainder is

used for cooling the walls of the flame tube.

There are three main types of combustion chamber in use for

gas turbine engines. These are the the multiple chamber, the

can-annular chamber and the annular chamber.

Multiple chamber

This type of combustion chamber

is used on centrifugal compressor engines and the earlier

types of axial flow compressor engines. It is a direct

development of the early type of Whittle engine

combustion chamber. Chambers are disposed radially around the

engine and compressor delivery air is directed by ducts into

the individual chambers. Each chamber has an inner flame tube

around which there is an air casing. The separate flame tubes

are all interconnected. This allows each tube to operate at

the same pressure and also allows combustion to propagate

around the flame tubes during engine starting.

A

multiple combustion chamber

Can-annular chamber

This type of

combustion chamber bridges the evolutionary gap between

multiple and annular types. A number of flame tubes are fitted

inside a common air casing. The airflow is similar to that

already described. This arrangement combines the ease of

overhaul and testing of the multiple system with the

compactness of the annular system.

A

can-annular combustion chamber

Annular chamber

This type of

combustion chamber consists of a single flame tube, completely

annular in form, which is contained in an inner and outer

casing. The main advantage of the annular combustion chamber

is that for the same power output, the length of the chamber

is only 75 per cent of that of a can-annular system of the

same diameter, resulting in a considerable saving in weight

and cost. Another advantage is the elimination of combustion

propagation problems from chamber to chamber.

power turbine

The turbine has the task of

providing power to drive the compressor and accessories. It

does this by extracting energy from the hot gases released

from the combustion system and expanding them to a lower

pressure and temperature. The continuous flow of gas to which

the turbine is exposed may enter the turbine at a temperature

between 850 and 1700 °C which is far above the melting point

of current materials technology.

A high-pressure turbine

stage from a CFM56 turbofan engine

To produce the driving torque,

the turbine may consist of several stages, each employing one

row of stationary guide vanes, and one row of moving blades.

The number of stages depends on the relationship between the

power required from the gas flow, the rotational speed at

which it must be produced, and the diameter of turbine

permitted. The design of the nozzle guide vanes and turbine

blade passages is broadly based on aerodynamic considerations,

and to obtain optimum efficiency, compatible with compressor

and combustor design, the nozzle guide vanes and turbine

blades are of a basic aerofoil shape.

A turbine blade with

cooling holes

The desire to produce a high engine efficiency demands a high

turbine inlet temperature, but this causes problems as the

turbine blades would be required to perform and survive long

operating periods at temperatures above their melting point.

These blades, while glowing red-hot, must be strong enough to

carry the centrifugal loads due to rotation at high speed.

To operate under these conditions, cool air is forced out of

many small holes in the blade. This air remains close to the

blade, preventing it from melting, but not detracting

significantly from the engine's overall performance. Nickel

alloys are used to construct the turbine blades and the nozzle

guide vanes because these materials demonstrate good

properties at high temperatures.

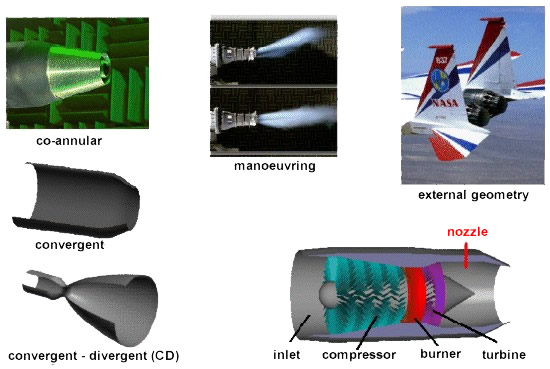

nozzles

All gas turbine engines have a

nozzle to produce thrust, to conduct the exhaust gases

back to the free stream, and to set the mass flow rate through

the engine. The nozzle sits downstream of the power turbine.

A nozzle is a

relatively simple device, just a specially shaped tube through

which hot gases flow. However, the mathematics which describe

the operation of the nozzle takes some careful thought. As

shown above, nozzles come in a variety of shapes and sizes

depending on the mission of the aircraft. Simple turbojets,

and turboprops, often have a fixed geometry convergent nozzle

as shown on the left of the figure. Turbofan engines will

sometimes employ a co-annular nozzle as shown at the top left.

The core flow will exit the centre nozzle while the fan flow

exits the annular nozzle. Afterburning turbojets and turbofans

often have a variable geometry convergent-divergent (CD)

nozzle as shown on the left. In this nozzle, the flow first

converges down to the minimum area, or throat, then is

expanded through the divergent section to the exit at the

right. The variable geometry causes these nozzles to be heavy,

but provides efficient engine operation over a wider airflow

range than a simple fixed nozzle. Rocket engines usually have

a fixed geometry CD nozzle with a much larger divergent

section than is required for a gas turbine.

All of the

nozzles we have discussed thus far are round tubes. Recently,

however, engineers have been experimenting with nozzles with

rectangular exits. This allows the exhaust flow to be easily

deflected, as shown in the middle of the figure. Changing the

direction of the thrust with the nozzle makes the aircraft

much more manoeuvrable.

Because the

nozzle conducts the hot exhaust back to the free stream, there

can be serious interactions between the engine exhaust flow

and the airflow around the aircraft. On fighter aircraft, in

particular, large drag penalties can occur near the nozzle

exits. A typical nozzle-afterbody configuration is

shown in the upper right for an F-15 with experimental

manoeuvring nozzles. As with the inlet design, the external

nozzle configuration is often designed by the air-framer. The

internal nozzle is usually the responsibility of the engine

manufacturer.

|