|

power turbine

The turbine has the task of

providing power to drive the compressor and accessories. It

does this by extracting energy from the hot gases released

from the combustion system and expanding them to a lower

pressure and temperature. The continuous flow of gas to which

the turbine is exposed may enter the turbine at a temperature

between 850 and 1700 °C which is far above the melting point

of current materials technology.

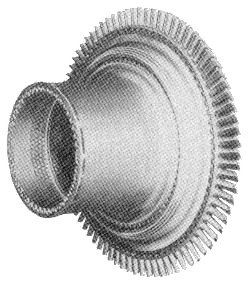

A high-pressure turbine

stage from a CFM56 turbofan engine

To produce the driving torque,

the turbine may consist of several stages, each employing one

row of stationary guide vanes, and one row of moving blades.

The number of stages depends on the relationship between the

power required from the gas flow, the rotational speed at

which it must be produced, and the diameter of turbine

permitted. The design of the nozzle guide vanes and turbine

blade passages is broadly based on aerodynamic considerations,

and to obtain optimum efficiency, compatible with compressor

and combustor design, the nozzle guide vanes and turbine

blades are of a basic aerofoil shape.

A turbine blade with

cooling holes

The desire to produce a high engine efficiency demands a high

turbine inlet temperature, but this causes problems as the

turbine blades would be required to perform and survive long

operating periods at temperatures above their melting point.

These blades, while glowing red-hot, must be strong enough to

carry the centrifugal loads due to rotation at high speed.

To operate under these conditions, cool air is forced out of

many small holes in the blade. This air remains close to the

blade, preventing it from melting, but not detracting

significantly from the engine's overall performance. Nickel

alloys are used to construct the turbine blades and the nozzle

guide vanes because these materials demonstrate good

properties at high temperatures.

|