|

power

plant accessories

The development of power plant accessory equipment goes back

to a period immediately following the first World War, when

flying was a haphazard and dangerous occupation. The only

flight instruments were a compass, bubble, altimeter and

tachometer. With these instruments, flights were occasionally

made through clouds but not for protracted periods. Very few

pilots were capable of flying blind even for the shortest

period. After the World War and at the beginning of commercial

aviation and the inauguration of airmail service in this

country most of the flying was of the contact type. The

development of the turn and bank indicator gave the first real

help in blind flying. Then came the artificial horizon and

gyro compass. The development of the radio range beam and

directional radio made it possible and practical to fly

without contact with the ground. With these instruments

available, the art of blind flying developed rapidly and

increased to the point where experimental flights entirely

with instruments from "take-off" to landing have been

successfully conducted.

Similarly, the development of the single

engine airplane of the World War period, with its engine of 30

horsepower, to the huge multi-motored transport of today,

wherein the output of a single cylinder is often equal to or

more than the total output of the early engine, has brought

about the development of power plant accessory equipment to

its present stage. The days of engine starting, wherein the

propeller was pulled through by hand, have long since

disappeared to be replaced by electrically operated Inertia or

Direct Cranking Electric Starters capable of transmitting 1500

pound feet of torque for the cranking of engines rated up to

2000 horsepower.

In a like manner, the development of

generating equipment from the early wind driven types having

an output of approximately 50 watts, to the engine driven

types of 3000 watts capacity, has also taken place. In

addition, the Venturi tube, which was subject to clogging with

dirt and ice, has long since been replaced with engine driven

vacuum pumps with capacities sufficient to provide proper

suction for the operation of navigating instruments and

pressure for the operation of wing and tail surface de-icers.

Whether the need has been for aircraft engine starting or for

the generation of electric power, accessory units have proved

vital necessities to the operation of the present day air

transport and military airplane. Electric motors for the

operation of retractable landing gear, wing flaps, tail

wheels, etc.; hydraulic pumps, valves and control units for

actuating hydraulically, full feathering propellers,

retracting mechanisms, etc.; radio dynamotors for the

operation of radio receivers and transmitters; fuel flow

meters for determining fuel consumption; these are only a few

of the many accessory units which have played an important

part in the development and dependability of the present-day

airplane. To the old time pilot the airplane may have

consisted primarily of the airplane and its engine, but to the

experienced air transport pilot of today aircraft accessory

equipment and flight instruments play a major part in

establishing flight security.

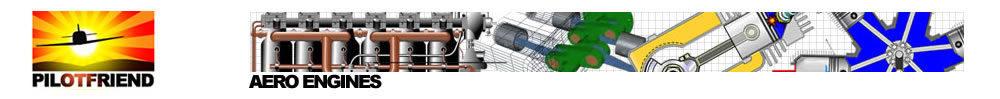

The fundamental requirements of any form of

aircraft power plant accessory are dependability, minimum

weight, simplicity of installation, ease of operation,

effectiveness, serviceability, and low initial cost. As the

number and type of power plant accessories are, necessarily,

limited to the number of drives available on the rear or

accessory drive section of the power plant, careful

consideration must be given to the number of operations to be

performed, and the type of

service to which the airplane is to be

subjected, prior to the selection of accessory equipment. In

addition, the capacity and type of accessory units to be

installed on a given power plant are definitely limited to the

physical characteristics, operating speed and torque

limitations of the accessory drives available.

Swinging the Prop

Although swinging the prop was the earliest

common form of starting for aircraft engines and the method

still in limited use for present-day light engines, there has

always been considerable danger to the operator when effecting

engine starting by this method. Swinging the prop, in most

cases, has been replaced by the use of either a hand turning

gear, air-injection starter, or direct cranking electric

starter, the latter two methods providing quick and convenient

starting by the pilot without need for external assistance.

The need for mechanical aid in starting, evolved many methods

which were short lived. Several, however, were successful to a

certain degree.

The Hucks Starter

An early advance in the development of

aircraft engine starting was the invention of the Hucks

starter, which was named after its inventor. This unit was an

external mechanical starter, employing a Ford motorcar

chassis. A special chain from the gearbox was made to drive a

layshaft mounted high up and adjustable. At the forward end of

this shaft was a coupling which could be made to engage with a

special "dogged" fitting attached to the propeller hub in the

same manner as a motor-car crank handle was used to engage the

engine crank shaft. Starting was effected by engaging the

coupling and rotating the layshaft. Disengagement of the

driving dog from the engine was automatic upon starting of the

engine. The Hucks starter, although an improvement over the

method of hand swinging was in turn, very impractical. Delays

in starting occurred when there were a large number of

airplanes to be started. Also, it was sometimes out of action

or did not exist at places where a start was required. At the

same time, it must be remembered that engines were increasing

in size and compression ratio to the point where swinging of

the propeller by hand as well as turning the propeller

mechanically by means of the Hucks starter were impracticable.

This brought about the development of the hand turning gear,

which is used in a modified form at the present time for

certain aircraft installations.

Hand Turning Gears

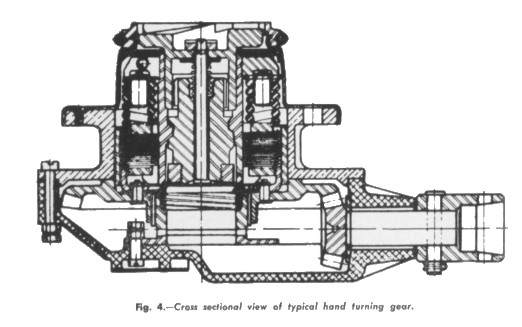

The development of the band turning gear

type of aircraft engine starter was primarily due to the need

for an aircraft engine starter capable of cranking engines

rated up to 600 horsepower not equipped with batteries or

generators. The hand turning gear consists, in general, of a

gear reduction unit, which operates an automatic engaging and

disengaging mechanism through an adjustable torque overload

release. Mechanical features are incorporated in the unit to

safeguard both the operator and starter from injury in case of

engine backfire. In case of the engine backfiring, the torque

overload release automatically disconnects the starter drive,

thus preventing damage to the starter mechanism. As a further

protection to the operator, a ratchet is provided in the hand

crankshaft to preclude the possible transmission of any

reverse motion to the crank-handle. Unusual care is exercised

in the design and manufacture of a hand turning gear to

eliminate friction, thereby assuring maximum even cranking. In

addition, the ratios of the gear reductions used have been

carefully determined in order to permit the highest engine

cranking speed consistent with the average manual effort which

can be expended in cranking. Thus, the operator is assured of

a prompt start with minimum effort, provided the other factors

which influence engine starting are normal.

|