|

air

injection

starter

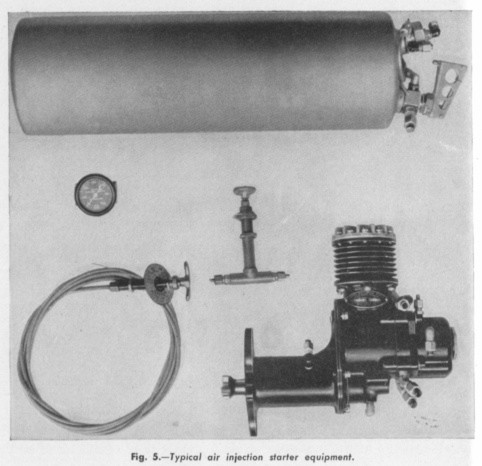

In limited use at the present time, the air injection starter

has been developed as a light-weight and efficient starting

means for aircraft engines rated up to 250 horsepower.

Operated from self generated air pressure, this type of

starter was particularly suitable for application on engines

of small output where an electrical installation was not

possible and manual hand-cranking undesirable and inadequate.

The Air injection starter equipment

consisted of a small and compact engine-driven air compressor,

a timed rotating distributing valve, integral with the

compressor, a tubular air storage tank, an automatic pressure.

regulating valve, pressure release starting valve, and an

instrument panel mounted pressure gauge and primer. However,

as the majority of light powered airplanes at the present time

are equipped with engines designed to accommodate a generator

of low output, the direct cranking electric type of starter is

replacing the majority of air injection starter installations

due to its light weight, simplified installation, and freedom

from service troubles. Due to the extensive plumbing required,

and the corresponding possibility of air leakage in the

system, the air injection type of starter is only recommended

for installations where battery and generator are not

available. Although primarily confined to use on engines rated

up to 250 horsepower, a starter employing this principle of

operation is widely used on foreign aircraft for starting

aircraft engines of all capacities.

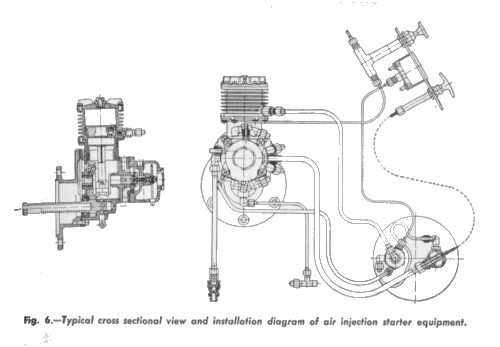

The principle of operation of the air

injection starter is as follows: The engine is cranked from an

initial air pressure of approximately 450 pounds per square

inch, which is contained in a storage tank. Release of the

compressed air is controlled from the pilot's compartment and

is transmitted by a distributor valve to the cylinders in the

proper cyclic order, thus rotating the engine. A portion of

the compressed air, in passing through the distributing valve,

forces liquid fuel into the cylinders on the compression

stroke. This carburettor priming charge is followed by a

greater volume of air which rotates the engine and assures

instant firing. The air pressure dissipated in starting is

replenished by the compressor shortly after the engine has

been started. As the maximum operating pressure of 450 pounds

per square inch is reached, the pressure regulating valve,

which is an integral part of the storage tank, automatically

stops further charging of the storage tank, thus the

compressor, driven direct from the main aircraft engine, is

temporarily relieved of pumping against pressure and rotates

freely under no load until further dissipation of the air

pressure by- starting occurs. Due to the variations which are

encountered in different installation, no definite performance

data can be given, however, under normal conditions,

approximately 20 to 30 starts can be obtained from one fully

charged tank of air without replenishment in the meantime.

Later Developments

Of more recent application in this country is the hand or

combination hand and electric inertia starters, which have

been designed primarily for use by the military services and

are suitable for installation on engines rated up to 2,000

horsepower. The starters are particularly suited for

installations where dependability and provisions for emergency

hand-cranking are required. The basic design of all inertia

starters consists of the storage of energy in a small flywheel

by accelerating it to a high speed either manually or

electrically. The energy thus stored is expended in rotating

the engine crankshaft. Transmittal of the kinetic energy of

the rotating flywheel to the engine is accomplished through

reduction gearing, a multiple disc clutch, an engaging

mechanism, and driving jaw.

|