|

aircraft engine

history

early

aircraft engines

At the start of the twentieth

century, aircraft engines were simple, low-powered machines

that were designed and built one by one for specific aircraft.

But very soon, engines started being built in quantity, often

by several manufacturers in different countries who were

licensed by the designer or initial manufacturer. In the

United States, particularly during World War I, automobile

manufacturers dominated the aero-engine field until companies

that specialized in aircraft engines were established in the

1920s.

A cutaway drawing of

the 1903 Wright Flyer engine.

The earliest aero engines were

stationary—either radial in style or in line. The Antoinette

series was the most commonly used. These were succeeded by the

popular rotary engine. The best known were the Gnome and Le

Rhône, which were used on the majority of aircraft until the

in-line Liberty engine, designed for mass production, started

dominating the aero-engine market. From that point on,

increasingly more sophisticated and powerful stationary

in-line engines were developed until the arrival of the jet

engine a couple of decades later.

The most

advanced aircraft engine early in the century was the

50-horsepower (37-kilowatt) engine designed by Charles Manley

for use on Samuel Langley's aerodromes. But because Langley's

aircraft never succeeded in flying, these engines did not have

the opportunity to demonstrate their potential. The engine

designed and built by Charlie Taylor and the Wright brothers

for their Flyer, although much lower powered, had a greater

place in history because it propelled the first successful

powered flight in 1903. Wright's engine had four inline

cylinders, was water-cooled, generated 12 horsepower (9

kilowatts) (as compared to Manley's 50 horsepower), and had

weighed about 179 pounds (81 kilograms) without the fuel. It

had no fuel pump, carburettor, or spark plugs.

This Curtiss

four-cylinder water-cooled engine was America's first military

aircraft engine. It was used to power the 1908 Signal Corps

Dirigible No. 1.

The Curtiss Aeroplane and Motor

Corporation produced two notable engines. A four-cylinder

water-cooled engine used in the 1908 Signal Corps Dirigible

No. 1 was America's first military aircraft engine. It could

generate about 25 horsepower (19 kilowatts) and drove a

22-foot (6.7-metre)-long tubular steel shaft that turned a

wooden propeller.

Lieutenant

Thomas Selfridge designed it. In its speed trial, it reached

19.6 miles per hour (31.5 kilometres per hour). Curtiss also

produced thousands of OX-5 water-cooled engines during World

War I, primarily for the Curtiss "Jenny." It generated only 90

horsepower (67 kilowatts) but, compared to other engines of

the period, was very reliable.

Thousands of Curtiss OX-5 water-cooled engines were produced

in the United States during World War I, primarily for the

Curtiss Jenny airplane.

The Antoinette engine was

designed and built in France by Léon Levavasseur. Named after

the designer's daughter, it was Europe's most widely used

engine until 1909-1910. The first Antoinette engine dated from

about 1901 and was used in a speedboat. By 1905, Levavasseur

had produced a water-cooled engine with eight-cylinders

arranged in a 90-degree "V" and with direct fuel injection. It

was safe, strong, and fairly powerful, generating 50

horsepower (37 kilowatts) and weighing about 110 pounds (50

kilograms). Its power-to-weight ratio was not surpassed for 25

years.

The French and

British-built Anzani 10 was an air-cooled radial engine that

was installed in French Caudron aircraft.

An Anzani engine carried Louis

Blériot's monoplane across the English Channel in 1909. It was

a three-cylinder, air-cooled, semi-radial engine that

developed 25 horsepower (19 kilowatts). It was relatively

low-powered for such a long flight. The engine had automatic

inlet valves and mechanically operated exhaust valves, with

auxiliary exhaust ports in the cylinders. Later Anzani engines

generated 90-100 horsepower (67-75 kilowatts) and were used in

French-produced Caudron aircraft in 1915.

The Gnome 9-N engine

was the first successful air-cooled rotary engine used

extensively in airplanes during the 1909-1910 period. Numerous

types of Gnome engines were designed and built, one of the

most famous being the 165-hp 9-N "Monosoupape" (one valve)

that was used during World War I primarily in the Nieuport 28.

The Gnome 50-horsepower

(37-kilowatt) rotary engine revolutionized aviation. Although

F.O. Farwell developed the first successful air-cooled rotary

engine in the United States in 1896, it was the French-built

Gnome rotary that was first used extensively in airplanes

during the first years of World War I. Designed by the Séguin

brothers and first marketed in 1908, it was the first of a

long line of ever more powerful wartime engines. A typical

rotary engine, it had a fixed crankshaft and rotating

cylinders and crankcase that carried the propeller with them.

Numerous types

of Gnome engines were subsequently designed and built. One of

the most famous was the 165-horsepower (123-kilowatt) 9-N "Monosoupape"

(one valve). The engine had one valve per cylinder. Having no

intake valves, its fuel mixture entered the cylinders through

circular holes or "ports" cut in the cylinder walls. It was

used during World War I primarily in the Nieuport 28, which

the U.S. Air Service purchased from France, and also by the

thousands in other Allied aircraft. This engine, produced

under the names of Bentley Rotary B.R.1 in Britain, the Thulin

in Sweden, and the Oberursel UR.I in Germany, dominated the

industry until 1916.

The Clerget rotary

engine was used in many Allied fighter planes during World War

I. One powered the famous Sopwith Camel.

Around 1911, other engine

manufacturers began building rotary engines. LeRhône and

Clerget engines, both built in France, were used in many

Allied fighter planes.

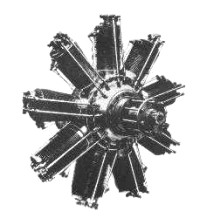

The LeRhone C-9 was a French air-cooled rotary engine. It was

used in combat airplanes early in World War I, but as larger

and more powerful engines became available, it was relegated

to use in training-type airplanes.

LeRhône engines were quite

reliable and, by the end of the war, were being manufactured

in Britain, Italy, and the United States in addition to

France. The Germans also produced the 110-horsepower

(82-kilowatt) Oberursel, which was practically an exact copy

of the 110-horsepower LeRhône. The Clerget powered Britain's

Sopwith Camel.

The Rolls-Royce Hawk was used in World War I British airships

sent against German U-boats.

The British Rolls-Royce Eagle and

its successor, the Falcon, marked the beginning of a famous

line of aviation engines that produced the Merlins and

Griffons of World War II. This liquid-cooled V-12 was

developed in 1915. It was built in several versions that

culminated with the 375-horsepower Mark VII of 1917. It

powered the Vimy plane that John Alcock and Arthur Whitten

Brown flew across the Atlantic in June 1919.

Mercedes

engines powered some of the best-known German fighter planes

in the last two years of the war—the Albatros D.V., Fokker D

VII, and Pfalz D XII. Nearly all German-designed engines were

durable and dependable, with six water-cooled cylinders in

line.

The Hispano-Suiza

8BE is a V-type liquid-cooled engine. This type of engine was

especially compact for the amount of power it produced and was

used in numerous types of aircraft.

A Swiss engineer of a Spanish car

company, Marc Birkigt, designed a number of Hispano-Suiza

products. These included a large number of water-cooled V-8

and V-12 engines that were made in France, Britain, and the

United States during the war. They were especially compact for

the amount of power they produced.

In 1916 and 1917,

Curtiss produced R-3 and R-4 airplanes that were powered by

the Curtiss V2-3 engine. Because this engine was heavy for the

amount of horsepower it produced, it was replaced during World

War I by the Liberty engine.

By far, the most important of all

Allied engines, and America's most significant contribution to

the war effort, was the Liberty. In May of 1917, Jesse G.

Vincent of the Packard Motor Car Company, and E.J. Hall, of

the Hall-Scott Motor Car Company, took over a hotel room in

Washington, D.C., for nearly a week and designed the eight-

and twelve-cylinder Liberty engines with mass-production in

mind.

The Liberty V eight-cylinder engine preceded the Liberty-12.

It was the first Liberty engine tested in an aircraft, on

August 29, 1917.

On June 4, 1917, the Aircraft

Production Board authorized final design, and manufacture.

Assembly of the first eight-cylinder version was completed in

the remarkably short span of less than six weeks.

The

eight-cylinder version debuted on August 29, 1917. It

generated 270 horsepower (201 kilowatts) initially but its

output was later boosted to 330 horsepower (246 kilowatts).

The initial version vibrated excessively and since another

engine with this capacity had already been perfected, its

development was halted after only 15 had been built.

America's greatest technological contribution during World War

I was the Liberty 12-cylinder water-cooled engine.

The Liberty 400-horsepower

(298-kilowatt) V-12, air-cooled engine, on the other hand, was

one of the war's most powerful engines and one of the

workhorses of the war. Designed to be mass-produced with

interchangeable parts, the Liberty became the standard wartime

aircraft engine, produced by Packard, Lincoln, Ford, General

Motors (Cadillac and Buick), Nordyke, and Marmon. It was used

most often on the DH-4, the only U.S.-made airplane to go into

combat on the Western Front. More than 13,000 engines came off

the assembly line before the Armistice, and more than 20,000

were built by the time wartime production ended early in 1919.

Following the

war, the Air Corps used the engine for more than a decade in

numerous types of airplanes. Some were sold to civilians as

war surplus and were illegally used in speedboats for "rum

running" during the Prohibition era of the 1920s. Others

proved their longevity by staying in use much longer, even

being used in Russian and British tanks during World War II.

|